Certifying confidence for specifiers

Specifiers need to know one thing about the systems they choose for a scheme: that they will perform effectively. With its commitment to robust, comprehensive product testing, Schüco can give architects that peace of mind.

When it comes to specifying for the building envelope, architects and specifiers need to be confident the systems they choose will perform as required. Schüco products undergo rigorous testing to ensure their robustness, durability and adaptability to perform under almost any conditions.

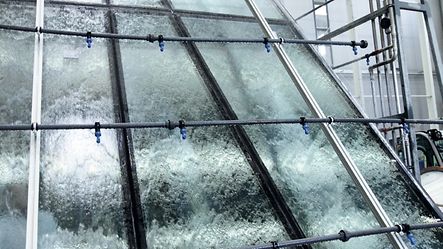

Independent testing in state-of-the-art facilities

Schüco products are reliable and durable because they undergo extensive performance testing in real-world conditions. This testing is carried out in specialised laboratories and is designed to demonstrate a system’s ability to perform under various loads, stresses, and environmental conditions.

The Schüco test centre in Bielefeld, Germany, is a state-of-the-art facility, used to test the systems of many leading building envelope suppliers. Unrivalled in Europe, the centre has the facilities to test a 3-storey façade sample.

The testing of Schüco products in Bielefeld is run independently by ift Rosenheim, an internationally recognised certification body. ift Rosenheim work with UK notified testing body UL Solutions to ensure Schüco products are tested to meet UK market requirements. This includes the PAS24 security certification and, from last year, the UKCA (UK Conformity Assessment) for all new Schüco products.

The UKCA mark is a declaration of performance under the UK’s Construction Products Regulation. It is set to replace the European standard CE mark on products sold in Great Britain and will become a mandatory requirement from 2025.

Schüco works closely with its testing partners to ensure all its aluminium and steel systems are comprehensively tested to meet - and exceed - all necessary requirements and regulations.

Comprehensive performance tests

Schüco products undergo rigorous testing programmes to ensure they will perform under a variety of demanding conditions.

All Schüco systems are tested for core performance characteristics including air permeability, water tightness, resistance to wind load, thermal transmittance and fire reaction. Schüco windows and doors are tested under the EN 14351 harmonised standard, and curtain walling under the EN 13830 harmonised standard.

The variety of system applications across the Schüco product range requires alternative testing. Windows and doors are tested for mechanical strength and burglar resistance, for example, whereas curtain walling is tested for resistance to dead load. Curtain wall systems may also be tested for characteristics like impact resistance.

Approved Document B outlines very specific requirements building elements must achieve in their reaction to fire. Elements that create a barrier or are involved in compartmentation, such as fire doors, are subject to thorough fire resistance testing. Their performance is declared through a fire rating which covers characteristics like system integrity, insulation and smoke control.

Schüco products are designed to perform to the highest standards of energy efficiency, with a range of systems Passivhaus certified. This involves measuring each system’s U-value, the result of which is heavily dependent on the type and thickness of the glass used. Schüco tests with a range of glass thicknesses to provide a known value achievable for each system and glass combination. Maximum U-values for Schüco products are based on the best commercially available glass.

Standard Schüco testing ensures a variety of product configurations are tested. For specifiers, this means that standard Schüco systems will be suitable to meet the performance and design requirements for the vast majority of schemes. Where a bespoke solution is required, however, customised testing is possible at additional cost.

Supporting fabrication

While Schüco does all that it can to ensure its products will perform as designed, the onus for the as-built performance of a system is on the manufacturer and installer. If a Schüco system is not manufactured or installed correctly its performance cannot be guaranteed.

Schüco works closely with its fabricator partners to make sure they are trained in its products and offers them access to, and training in, the latest fabrication technologies. It also encourages fabricators to complete CPDs on topics like fire standards and regulation.

Where Schüco partners are manufacturing external fire rated products, Schüco supplies to them on the condition that fabricators submit to legally mandated factory product control audits. The independent inspections verify that manufacturers are making products correctly to ensure that they will perform in line with the designed fire rating.

By choosing Schüco products, specifiers can be confident that there is a thorough chain of evidence to verify system performance. They also know that they are working with expert fabricators supported by Schüco in manufacturing its products to achieve the high-performance characteristics built into their design.

For information about system performance and certification visit the product pages on our website or NBS source. We also recommend contacting a Schüco Architectural Project Manager for project-specific advice to help you specify the right Schüco products for your scheme.