Winner of the Refurbishment Projected Award

Coal Drops Yard

Designed by Heatherwick Studio, Coal Drops Yard forms the centerpiece of a vibrant new shopping district in London’s Kings Cross. Comprising more than 50 shops and restaurants, the development has been sympathetically crafted around the site’s existing Victorian architecture.

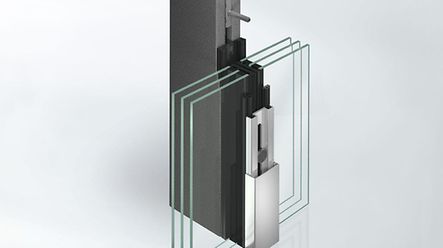

The Schüco Jansen ‘suite’ of steel systems was specified to complement the building’s industrial aesthetic, as well as to deliver high fire ratings, large-format glass panels, structural integrity, excellent thermal performance and slim sightlines. The decision to retain the original brickwork and other features proved challenging, as every hand-built arch is different to the next. Each profile has therefore been individually rolled and manufactured to accommodate a specific archway and its surrounding cast iron pillars, fish-plates, beams and concrete upstands.

Specialist contractor Propak Architectural Glazing was appointed at an early stage by main contractor BAM Construct to develop the detail design. In total, Propak manufactured and installed more than 150 arched shop fronts. These include large-format curtain wall systems, thermally broken dual-action doors, fire-rated glazed steel doors for both integrity and insulation, thermally broken steel heritage-style windows, steel bi-fold doors, and fire-rated steel curtain walling.

Historic variations in the brickwork have produced irregular gaps around the arches. To overcome this, Propak adapted the Schüco Jansen system by laser cutting a skeleton-shaped angle to clip into the arch. This ensures a consistent shadow gap around the perimeter of the frame.

Despite employing single mullions that span up to 5.5 metres, the profile face width has been kept to a minimum through the use of a complex spigot reinforcement system. Propak was able to engineer the Schüco Jansen system to accommodate back box sections measuring just 50 x 80 mm.

The specialist contractor was also able to reduce construction costs by eschewing the proposed automatic door system in favour of its own bespoke concealed breakout system. This allows the doors to open inward during normal use and outwards in the event of an emergency – without recourse to expensive electronic closing devices.

The jury applauded the quality and consistency of the interfaces between the scheme’s old and new elements. Equally importantly, it felt that project team had selected the right products for the job.