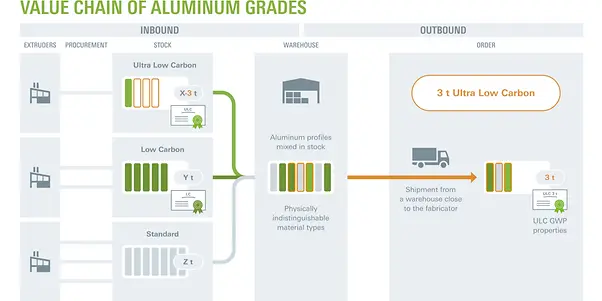

The distribution of Schüco Low Carbon (LC) and Ultra Low Carbon (ULC) profiles is organised in accordance with the allotment process. The priority here is for the ordered profiles to reach their destination in the most efficient way possible with the shortest transport routes. In order to ensure this, we do not differentiate between the different material grades of standard aluminium, Low Carbon aluminium and Ultra Low Carbon aluminium for storage and delivery. This also isn't necessary, as the material grades are identical in chemical, mechanical and geometric terms.

The relevant carbon saving is made beforehand, during the production stage. Low Carbon and Ultra Low Carbon aluminium have a considerably smaller carbon footprint and therefore a lower Global Warming Potential (GWP) than standard aluminium. The profiles supplied may therefore consist of standard, LC or ULC aluminium, irrespective of what has been ordered.