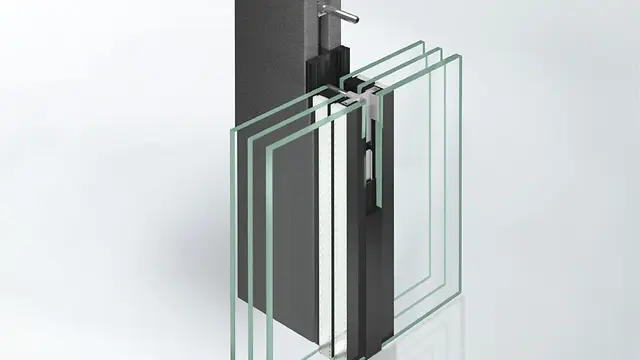

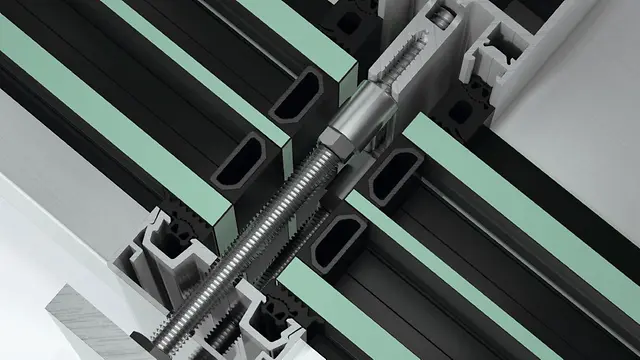

Installing the up to 800 kg curtain walling units behind the primary steel construction posed a significant challenge. At the top and bottom end, the Schüco VISS SG curtain wall is fixed to the primary construction by means of project-specific, custom-made glazing clips. It is unsupported laterally, so that it can sway with the building. Two steel mullions and a U-shaped profile have been joined together in such a way that they appear unsupported in one length, and are then cloaked to appear seamless. The glass-to-glass corner joints proved to be particularly challenging. For this, the standard VISS SG profile was modified to allow it to be installed at a 45-degree offset, to maintain the glass edge support on both sides. The mullion, which has been reduced as much as possible in terms of form, provides an optimum view to the outside.