5-axis and multi-axis CNC machines

5-axis milling machines and multi-axis CNC machines

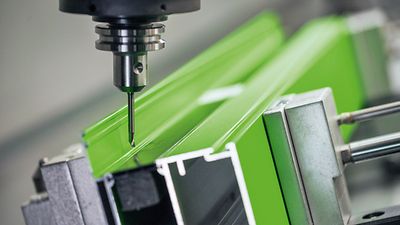

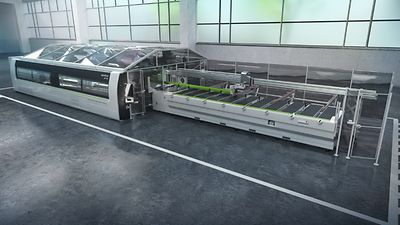

From raw bars to the finished component with just one machine: 5-axis and multi-axis milling machines take on the cutting, bar processing, complex notches and 3D processes easily and efficiently. Optimise your entire fabrication process with CNC milling machines from Schüco.

More information about 5-axis milling machines and multi-axis CNC machines

The benefits of Schüco 5-axis milling machines

The benefits of Schüco 5-axis milling machines

- Complete complex 3D processing with ease

- Cutting, milling, drilling and notching on just one machine.

- Machining of very large profile dimensions

- Greatest possible flexibility with maximum precision

- Increase efficiency and free up employees

- The fabrication process is made much more simple

- The range of technological possibilities is expanded

- Faster machining with increased quality

- Reduced wastage

- Employees are freed up and have more time for other work

What is a 5-axis CNC machine?

What is a 5-axis CNC machine?

The 5-axis milling machine works with five main axes fixed to a frame. With this type of CNC machine, all 5 axes can be moved on the main X, Y and Z axes. What's more, the 5-axis CNC milling machine can also be rotated on the A, B and C axes. This is where the key advantage comes into play, as the additional pivot and rotation axes make integrated 3D processing possible.

The 5-axis milling machine is one of our most state-of-the-art, advanced machines. Work with our 5-axis CNC machines can also be further optimised by means of innovative robot technology.

What are the 5 axes when milling?

What are the 5 axes when milling?

The 5-axis milling machine is fitted with 5 axis heads, whereby each axis has a different function. The functions of a CNC machine with 5 axes are easy to explain:

- The X axis moves from left to right

- The Y axis moves forwards and backwards

- The Z axis moves up and down

- The A axis rotates 180° around the X axis

- The B axis rotates 180° around the Y axis

- The C axis rotates 180° around the Z axis

Areas of application for 5-axis CNC machines

Areas of application for 5-axis CNC machines

5-axis CNC machines can really do it all. Their uses range from A to Z, but of particular note is their ability to make particularly large and deep cuts.