Saws

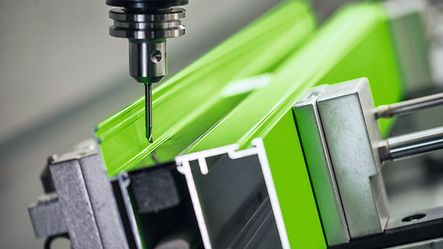

High-quality saws for metal fabrication

A high-quality saw for metal fabrication is an essential for every workshop involved in the industrial-scale fabrication of metal goods, material and objects. With an extensive offering of different metal saws and sawing machines, Schüco has the right machine for your needs.

Specific requirements? No problem.

Whether you require profile cuts, compound-mitre cuts or custom mitre cuts, with our range of saws we have the tools to meet your requests and requirements and will find the right machine for your fabrication.

Industrial saws – the basics

What kinds of saw are there?

What kinds of saw are there?

At Schüco, we distinguish between five types of saws for machining metal, as follows:

- Double-headed mitre saws

- Glazing bead saws

- Cross-cut and mitre saws

- Notching and compound-mitre saws

- Steel saws

This range of saws allows us to ensure that the right saw is always used for the right task. From the classic metal saw to the modern electric saw, we can provide you with the right saw for your application.

What is a metal saw?

What is a metal saw?

A metal saw is a machining tool that is used to cut through metal workpieces. Handheld metal saws and sawing machines for metal materials are different. Schüco focuses on sawing machines for metal fabricators. The basic components of a metal saw are:

- A saw blade or bandsaw blade

- A guide mechanism or holder

- Guide rollers or brackets

- Motor

- A workpiece holder

The saw blade or bandsaw blade (continuous) carries out the actual work of cutting through the metal workpiece. It consists of a tough, hard material and has a significantly finer pitch than saw blades for woodworking. The saw blade is driven by a motor and moves in a uniform or oscillating manner. It is pressed against the workpiece and removes a shaving of material with every cutting stroke.

What is special about metal saws?

What is special about metal saws?

Metal saws are generally designed to work optimally at the specific feed rates and cutting speeds and to be robust and stable so as to withstand the exacting demands of metal machining. In addition, these saws include auxiliary features that are also highly specific to this type of saw, including:

- A coolant/lubricant supply

- A workpiece clamping mechanism

The saw blades for a metal saw consist of a tough, hard material. The choice of material depends on what metal you want to cut with the saw. Another special characteristic of a metal saw is that it can only cut straight or with a large radius due to the height of the saw blade.

The basic operation of metal saws

The basic operation of metal saws

The saw blade can be driven in a uniform or oscillating mode. Each cutting stroke corresponds to the removal of a shaving from the workpiece. The movement of the saw blade simultaneously removes the shaving from the cut. The systems behind the metal saw ensure that several teeth of a saw blade or bandsaw blade are always in contact with the workpiece. The quality of the cut depends on various factors, the most important of which are as follows:

- Type and composition of the saw blade

- Saw blade pitch

- Cut speed

- Coolant/lubricant

The workpiece material also determines the shape of the teeth. As a general rule, the softer the workpiece is, the smaller the cutting angle may be. Generally, metal saws can be categorised as follows:

- Hacksaws

- Bandsaws

- Circular saws

How complex is it to operate a metal saw?

How complex is it to operate a metal saw?

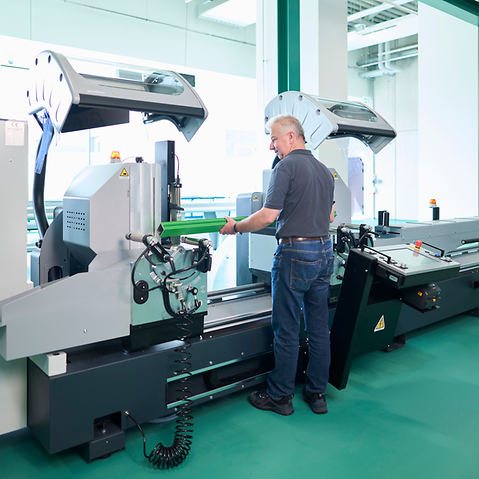

Schüco metal saws are intuitive and easy to operate. In general, they are operated either manually or automatically.

When the saw is manually operated, like the Schüco 215 NS compound-mitre saw, for example, operating elements such as a hand crank are used. The hand crank is used to set the saw to the desired angle via a worm gear, and you can then begin the sawing process. Manually operated saws are suitable for smaller, more simple sawing operations in particular. Automatic metal saws are suitable for more complex tasks and for processing larger orders due to the significantly higher level of efficiency.

Automatic operation generally refers to computer numerical control (CNC). This electronic process is used in various machine tools. In general, a number of different axes are automatically controlled. Knowledge of CNC is required to operate a machine of this kind.