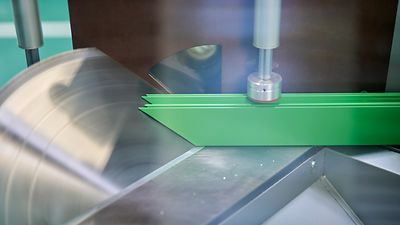

Double-headed mitre saws

Double-headed mitre saws for aluminium profiles

As a machine tool, a conventional saw will often not be suitable for the task of cutting aluminium profiles, be it for window or door profiles. This requires the use of a special type of saw: the double-headed mitre saw. This special type of saw will help you with your workflow, save time and elevate your work to new heights.