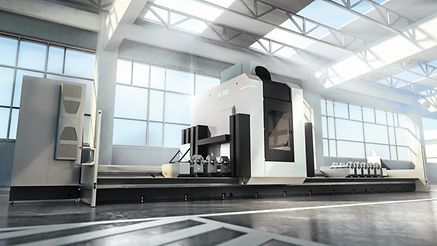

CNC machines

Efficient CNC machines from Schüco

Precision, efficiency and speed during metal fabrication. Schüco CNC machines are tailored to the individual needs of our partners. Whether it's four-axis machines, five-axis machines or multi-axis machines – our machines support fabricators and offer long-term added value for fabrication processes.

What our metal fabrication partners say

We always work closely and side by side with our partners in order to get the best-possible CNC machines and solutions for fabrication, and to obtain the best results.

CNC machines – the basics

What does CNC mean?

What does CNC mean?

The term CNC (Computerized Numerical Control) describes the computerised control of machines that work across multiple dimensions. The use of control technology means that CNC machines are able to process workpieces precisely with different tools based on existing specifications. CNC also enables you to fabricate complex workpieces in large quantities and with a consistently high quality. This means CNC machines are a fixed part of industrial fabrication and form the basis for efficient production. This process is suitable for a wide range of materials, including metals, the speciality area of Fabrication Products.

What are the benefits of a CNC machine?

What are the benefits of a CNC machine?

- Precision – Precise fabrication thanks to the computer-controlled data provision.

- Conserves resources – Efficient use of materials as the digital data availability means that work is extremely precise.

- Future-proof – Demographic change and the lack of skilled workers are a challenge for every company. Free up your employees by using our CNC machines.

- Easy operation – The machine is easy to use as the data is taken from the software.

- Frees up employees – Complex work steps are made easier by the CNC machine with simple operation, freeing up employees. One employee can load the CNC machine and fabrication is largely autonomous.

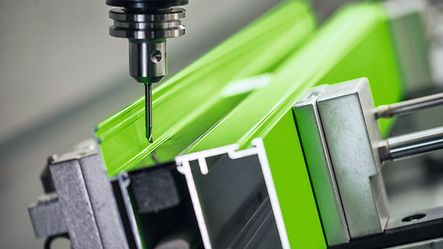

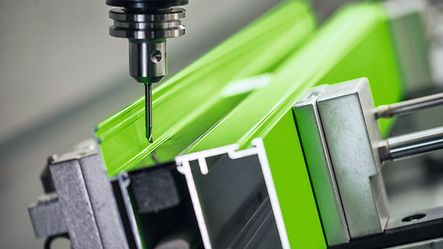

Which process steps are performed with CNC?

Which process steps are performed with CNC?

Our CNC machines are multifunctional tools that are tailored to your specific requirements. Optimise your work steps for cutting, milling, drilling and notching with our innovative CNC machines. From machining system profiles, 3D processing and jack rafter cuts through to simple drilled holes – there are no limits to what they can do.

Take the first step towards automating craftsmanship with Schüco and the RX LOAD 500 robot cell. Our 5-axis AF 500 and AF 510 CNC machines can be upgraded with a robot that takes on loading and unloading of the machine. This means that your employees are freed up and future-proofs your fabrication process.

How complex is it to operate and control CNC machines?

How complex is it to operate and control CNC machines?

When working with Schüco CNC machines, neither control nor operation is complex. For the greatest-possible efficiency, reliable error prevention and high quality at the same time, we keep our software clear simple. The software can also complete complex tasks itself such as clamp positioning, collision prevention or tool selection. You always retain control and can easily program yourself directly on the machine or in your office. Copy data directly from SchüCal or other calculation programs quickly and easily.

How many axes can a CNC machine have?

How many axes can a CNC machine have?

CNC machines can have between 3 and 12 axes. Our range covers all relevant options:

How many axes do I need in my CNC machine?

How many axes do I need in my CNC machine?

This individual question should always be answered following consideration of your needs. Our experts will be happy to advise you on this – we'll find the perfect solution for your fabrication process.