Schüco Window System LivIng

Schüco LivIng – the new system generation for pioneering PVC-U windows

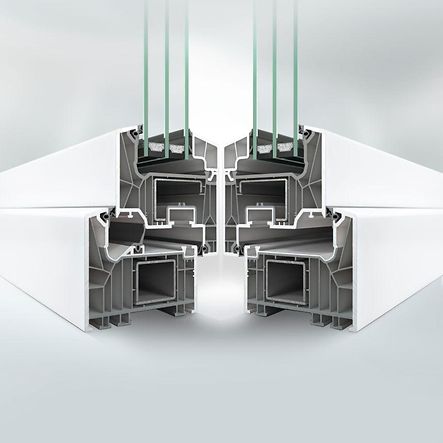

Based on twin system technology, the Schüco LivIng window system offers impressively simple, efficient and flexible fabrication and installation. It also meets the highest standards of comfort and safety with a huge range of design and construction options.

With the Schüco LivIng PVC-U system, Schüco is setting standards for steel-reinforced profile systems when it comes to energy efficiency. The innovative 7-chamber system, which can be constructed as a twin system with both a rebate gasket and a centre gasket, achieves excellent thermal insulation values with a basic depth of 82 mm. As a centre gasket system, it achieves passive house standard without any expensive and time-consuming additional measures.

A weldable premium seal is integrated into the Schüco LivIng window system. Using elastic, weld-on material increases the sealing effect in the difficult corner area of the unit, whilst also allowing for a closed, visually appealing corner design without hard gasket corners. The durable, eco-friendly material keeps a tight seal throughout its entire service life.

The Schüco LivIng series can be designed with three vent contours – Classic, Rondo and Viva – and also offers many different attachment and supplementary profiles: the twin system can therefore meet the individual needs of any client, whether for private residential homes, commercial projects, new builds or renovations.

The PVC film range Schüco UnlimitedFinish and Schüco TopAlu are available for colour designs. The basic profile bodies are also available in different colours to match the surface design.

White Schüco LivIng profiles are supplied with modern, silver-grey gaskets, foiled profiles are available with black gaskets.

Fabrication benefits

- Same reinforcement profiles can be used for outer and vent frames

- Special vent frame profile for the use of adhesive technology

- High-quality functional gaskets machine-rolled in the factory, can be welded

- Due to a special, patented technology for welding the profiles, the gaskets do not require any additional processing

- Glazing bridge with self-locating clamp for secure and easy installation

- Cliphook on the double-vent profiles as a positioning aid for simple installation and central screw connection

- Due to 5 mm gasket clearance between the outer and vent frames, the vent rebate gasket does not need to be notched in the turn/tilt mechanism pivot area

- Identical system dimensions, e.g. glass deduction during fabrication with rebate and centre gasket

- Reduced variety of parts means lower storage costs and less work with orders

- T-cleat can be used with all centre gaskets, which removes the need for notching the centre gasket