Looking for simple window fabrication?

Make your window in just a few easy steps.

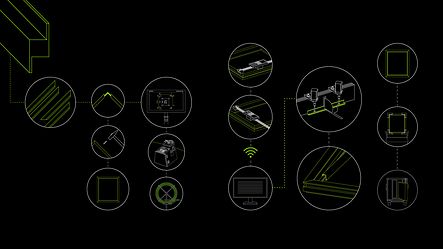

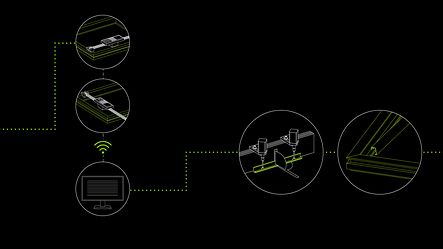

The Schüco turn/tilt window consists of over 100 individual parts. Together they create a window of outstanding quality. In order to fabricate these parts efficiently, you need the right process. The individual steps are tailored, digitally linked and precise, ensuring perfect results for every Schüco partner, no matter what size they are.

How does it work? Take a look for yourself!

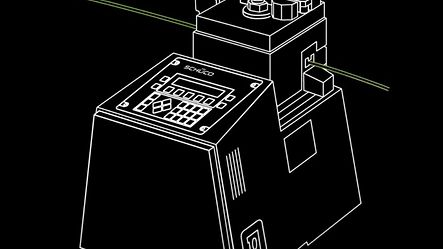

"Locking bars and glazing bead fabrication are among the most time-consuming tasks when constructing a window and have a huge impact on the quality of the units. Our glazing bead saws and locking bar machines ensure a highly reliable process with consistent high quality and reduced fabrication times."

Alexander von Bobart, workshop advisor, Schüco International KG

Do you have any other questions?

Our workshop advisers will be happy to help you.

We would be happy to look at your workshop and give you helpful individual advice for efficient window fabrication.

Workshop planning