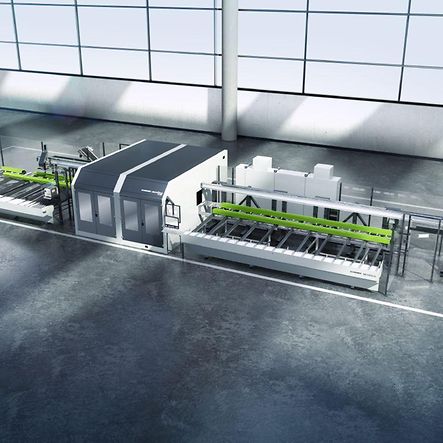

Schüco VX 800

Increased speed. More control. A bigger future.

The Schüco VX 800 machine sets new standards in modern aluminium profile processing. As a highly specialised processing centre, the machine combines precision and efficiency for processing even the most varied aluminium profiles and building components. With a reliable welded construction, automated feed systems and high-precision measuring devices, the VX 800 is designed to maximise productivity and significantly speed up machining processes. The machine combines processing flexibility with the highest standards of quality and innovative safety functions. Whether cutting, milling or measuring, the VX 800 offers a complete solution for sophisticated fabrication requirements, supported by state-of-the-art software solutions and intuitive operation. Feel the benefit of increased efficiency, reduced material waste and a machinery concept that meets the growing requirements of the construction industry.

Fabrication benefits

- With a processing speed of up to 180 m/min, the VX 800 sets new standards in terms of productivity, allowing maximum output with uncompromising precision.

- Fully automated where it really counts: from loading right through to labelling, everything is done automatically which saves time, reduces costs and creates space for essential tasks.

- The VX 800 adapts to your workflow: whether 3-axis or 5-axis machining, label printing or handling short components, the modular design covers all bases.

- More from every metre: thanks to intelligent software and fully automated optimisation, off-cuts are reduced to a minimum enabling maximum cost-efficiency.

- Total power with maximum control: up to six high-frequency spindles and integrated vibration sensors ensure uncompromising performance without damaging the tools.

- The intelligent measurement technology and automated tolerance detection ensure perfect cutting, which allows maximum utilisation of materials without refinishing.

- CNC has never been easier: the intuitive 3D user interface makes complex processes easy to understand, even for beginners. High-tech and easy to use.

- Ready for Industry 4.0: can be fully networked with SchüCal and remote support, making the VX 800 the digital hub for the fabrication of tomorrow.