Alongside this, we are experiencing an increase in demand for low-emission products in various European markets, including the UK, Denmark, Norway and the Benelux states. Outside of Europe in our growth markets of China, India and the Middle East in particular, we are seeing above-average growth, albeit currently with a limited supply of low-carbon raw materials. Demand in these regions is also not yet sufficiently developed, meaning that momentum for low-emission products has not yet resulted in a high level of sales. The result is that our company-wide greenhouse gas emissions have risen compared to the previous year.

We identified the developments outlined here at an early stage and, following initial successful additions to our portfolio, we are now increasingly focusing our attention on the growth markets outside of Europe. One key area we are concentrating on is the greater integration of our purchasing departments worldwide. They are very important when it comes to systematically increasing the proportion of low-emission materials and overcoming regional differences. We are also further expanding our collaboration with our suppliers, in particular with regard to the use of recycled materials.

Furthermore, we are gradually expanding our return systems. These will ensure access to high-quality secondary raw materials in future and are strategically important levers for change with regard to decarbonisation – even if their impact is not yet reflected in current emission data.

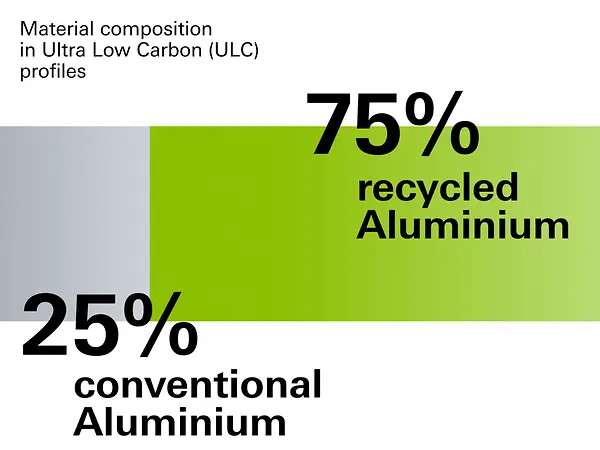

The measures that we have introduced are already showing initial signs of success. We have been able to significantly lower the carbon footprint of our material grades by increasing our use of green energy and recycled materials. This has enabled the Global Warming Potential (GWP) of the Schüco Low Carbon (LC) aluminium profiles to decrease from 4.14 kg of CO₂e per kilogram of profile to 3.84 kg of CO₂e. For our Ultra Low Carbon (ULC) profiles, we were able to reduce the GWP value from 2.27 to 1.99 kg of CO₂e per kilogram. This value has been achieved above all by using post-consumer recycled material, of which the profiles contain at least 75%. The new GWP parameters were confirmed at the start of 2025 by independent profile EDPs.

By converting from polyamide insulating bars made from PA 66 GF 25 to recycled materials in all product groups, Schüco has completed the next step in its sustainability strategy. Compared to polyamide insulating bars made from new materials, the use of recycled polyamide enables more than 65% of the CO₂e to be saved.

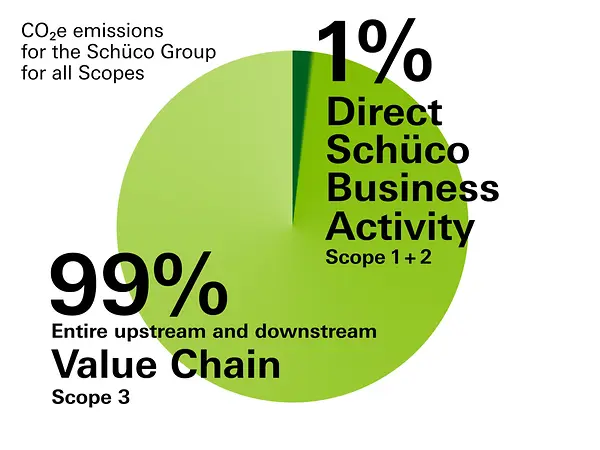

As can be seen, the decarbonisation of our value chain is not a linear process, but a global task. A deciding factor will be to decouple our sales even more consistently from carbon emissions in future, by means of holistic products and services, market intelligence and reliable partnerships.