Milling, drilling, punching

End milling machines

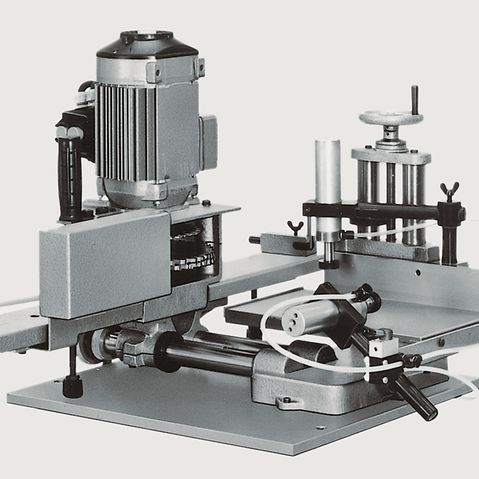

AKF 4

AKF 4

For accurate milling of the ends of sash bar, transom, mullion and sill profiles for T-joints, and of door profiles for the base point.

- Milling area (depth x height) 80 x 140 mm.

Technical data:

Motor: | 400 V / 2 kW |

Material support shoulder: | +20° / 90° /-20° |

Module position: | 90° |

Milling diameter (max.): | 250 mm |

Milling packages height (max.): | 90 mm |

Milling depth: | 80 mm |

Profile width (max.): | 350 mm |

Profile height (max.): | 140 mm |

Profile length (min.): | 400 mm |

Extraction nozzle diameter: | 80 mm |

Weight: | 95 kg |

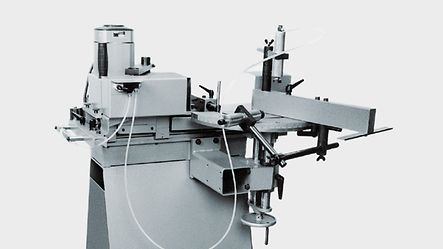

AKF 6

AKF 6

For accurate milling of the ends of sash bar, transom, mullion and sill profiles for T-joints, and of door profiles for the base point.

- Milling area (depth x height) 85 x 150 mm.

Technical data:

Motor: | 400 V / 3 kW |

Material support shoulder: | +20° / 90° /-20° |

Module position: | 90° |

Milling diameter (max.): | 250 mm |

Milling packages height (max.): | 90 mm |

Milling depth: | 85 mm |

Profile width (max.): | 305 mm |

Profile height (max.): | 150 mm |

Profile length (min.): | 400 mm |

Extraction nozzle diameter: | 80 mm |

Weight: | 190 kg |

AKF 8

AKF 8

For accurate milling of the ends of sash bar, transom, mullion and sill profiles for T-joints, and of door profiles for the base point.

- Milling area (depth x height) 100 x 180 mm.

Technical data:

Motor: | 400 V / 2.2 kW |

Material support shoulder: | 90° to 20° (left) / 30° (right) |

Module position: | 90 and in 15° increments |

Milling diameter (max.): | 250 mm |

Milling packages height (max.): | 160 mm |

Milling depth: | 95 mm |

Profile width (max.): | 300 mm (at 90°) |

Profile height (max.): | 180 mm |

Profile length (min.): | 300 mm |

Extraction nozzle diameter: | 80 / 90 / 100 mm |

Weight: | 400 kg |

Copy routers

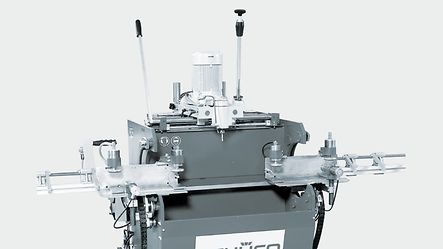

KF 348 and KF 347

KF 348 and KF 347

For precise machining of the recesses for locks, including cylinder locks, and handles with gearboxes on door and window profiles.

- KF 348: Aluminium and steel processing

- KF 347: Aluminium processing

Technical data:

Motor: | 400 V / 1.5 kW (KF 348 change-pole motor) |

Profile rotation: | 180° |

Working position: | 0°, 60°, 90°, 180° |

Profile width (max.): | 120 mm |

Profile height (max.): | 100 mm |

Profile length (min.): | 500 mm |

Profile length (max.): | 3000 mm |

Weight: | 300 kg |

Drilling machines

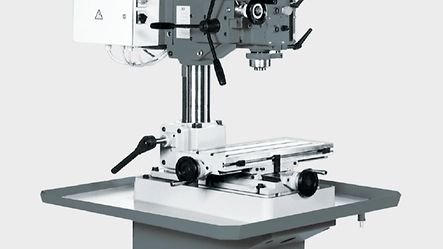

Drill and Mill Cutter BT 25 F

Drill and Mill Cutter BT 25 F

For all types of machining and drilling.

Technical data:

Motor: | 400 V / 0.8 / 1.5 kW (change-pole motor) |

Speed: | 120 - 2160 min-1 |

Sleeve stroke: | 100 mm |

Distance between spindle/table: | 80 - 450 mm |

Range of travel X-axis: | 350 mm |

Range of travel Y-axis: | 160 mm |

Spindle support: | MK 3 |

Weight: | 340 kg |

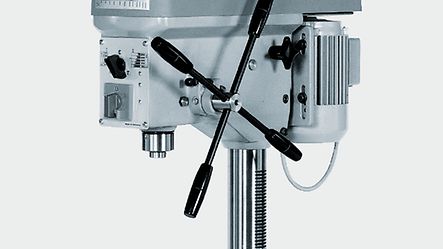

Bench drilling machine BT 18

Bench drilling machine BT 18

For setting drill holes.

Technical data:

Motor: | 400 V / 0.7 / 1.3 kW (change-pole motor) |

Speed: | 240 - 3800 min-1 |

Drilling depth: | 100 mm |

Distance between spindle/table: | 150 - 450 mm |

Distance between spindle/base plate: | 560 mm |

Spindle support: | MK 2 |

Weight: | 85 kg |

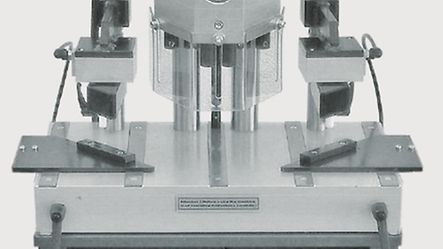

Door hinge drilling machine

Door hinge drilling machine

For simultaneous drilling of fixing holes for 2-part and 3-part Schüco door hinges in the outer and leaf frames.

Technical data:

Motor: | 400 V / 1.1 kW |

Speed: | 2800 min-1 |

Weight: | 90 kg |

Presses

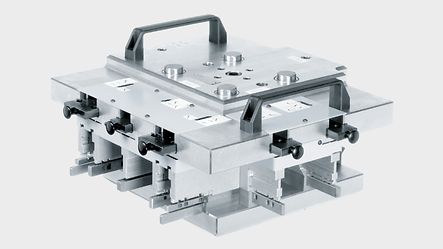

Base press

Base press

Designed for the new compact tool and the new generation of press tools

- Lifting height: 20 mm

- Fixing options for length stops and brackets

- Rapid tool change using fast fit systems (tool is ready to use immediately once fitted onto the base press)

- Compact tools are held on the base press using a friction bearing and alignment pins

- Unrestricted tool height

- Safety switch for tool assembly

- Adapter for the next generation of press tools

- Increased user protection

- Installation on machine base, Art. No. 299 504 possible

Hand press

Hand press

Designed to accommodate Schüco tool inserts.

- Lightweight, compact, versatile

- Minimum space required for storing different tools

- Easy to use thanks to attached handle

- Operated using a button on the handle

- Quick change of tools thanks to simple handling

- No need to remove hand press from compressed air supply when changing tools

- Security pin between press and tool

- Increased user protection

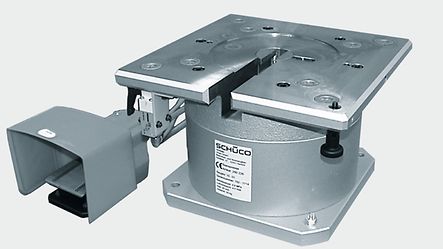

Hydraulic press

Hydraulic press

Designed for Schüco combination presses and the new generation of press tools. The hydraulic press works more quickly and with greater power than the base press.

- Lifting height: 20mm

- Minimum space required

- Compact design operated by foot pedal

- Fixing options

- Unrestricted tool height

- Adapter for the next generation of press tools

- Integrated machine base

Hydropneumatic hand press

Hydropneumatic hand press

Designed for Schüco tool inserts.

- Minimum construction means it is a very economical system

- Handle to operate with punch

- Rapid tool changing

- Security pins between press and tool

- Improved work protection

Combination presses

Combination presses

Can be used for different series

- Excellent cost-performance ratio

- Logical sequence of steps in one punching operation

- Integration of multiple process steps in a single combination press

- Easy handling through use of the attached handles

- Multifunctionality means no need to change tools constantly

- Can be used for all series

Punches

Hand punch

Hand punch

Used in special cases, for punching Schüco profiles.

- Easy-to-operate using handle

- Operated using a button on the handle

- Plastic handle

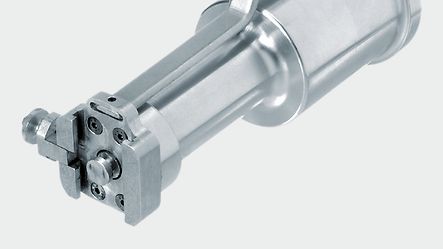

Transom punch

Transom punch

For punching 4.2 x 7 mm slots in the transom profiles for the façade systems.

The transom punch can be used for a variety of façade systems.

- Operated using a foot pedal

- Can be installed on machine base Art No. 299 504

- Moving punch

- Integrated pneumatic cylinder

- No height restriction for transom preparation

- Punches transoms even with pre-mounted isolators

- Can punch before or after the transform has been notched

- Can be used for all series, e.g.: FW 50+, FW 60+

Please note

We reserve the right to make changes to dimensions and designs in the interest of technical progress.

Illustrations may differ from the original and/or contain options which would incur an additional charge.

Many benefits as a registered user:

- Work material (e.g. tender specifications, CAD data, catalogues)

- Software & Tools

- Note content

- Direct contact to Schüco