The Schüco Group develops and sells system solutions for windows, doors, façades, sliding systems, sun shading systems, ventilation systems and fire protection systems, which are available in the form of around 500 series in total. We also work with our partners to create individual special constructions. Added to this are approximately 50 different fabrication machines, as well as planning, drawing, calculation and project management software. A wide range of comprehensive customer training courses rounds off the product portfolio.

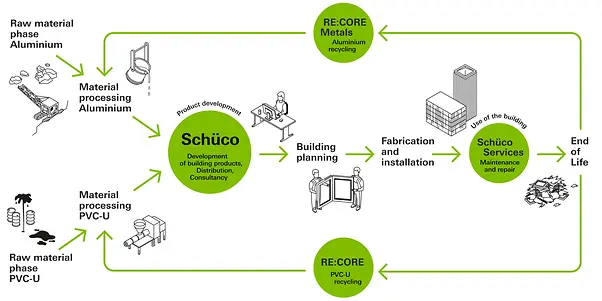

Our core competencies lie in development, procurement, distribution and consultation. This includes advice on certifications, design using sustainable systems, and help with environmental product declarations. We offer solutions for all phases of a building project – from the initial idea, design, fabrication and installation all the way through to after-sales service including maintenance and servicing.

With 6867 employees worldwide, we are working on becoming the leading provider of circular solutions and services for sustainable building envelopes. In order to achieve this aim, we consistently focus on the needs of our customers, which include architects, planning offices, investors and specialist metal fabrication and window construction companies all over the world.