By designing and providing durable, recyclable products we are helping to extend the duration of their use and close resource cycles.

At project level, Schüco is driving forward the Cradle to Cradle certification of its aluminium systems. With 95 certified systems, which account for 20% of the metal division's turnover in Europe, Schüco is an industry pioneer in the implementation of the Cradle to Cradle principle.

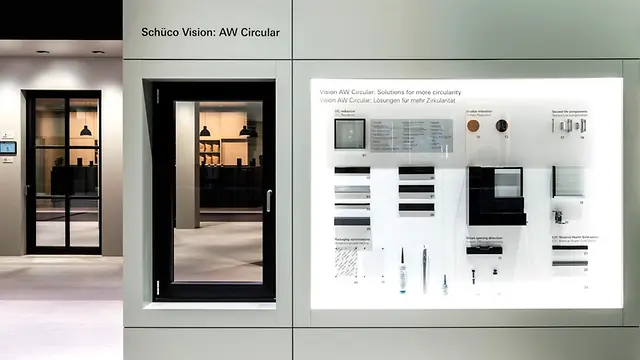

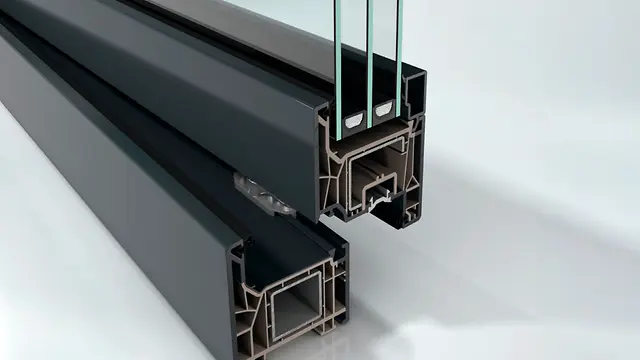

During the reporting period, Schüco also undertook extensive research into the principles of circular design. At the BAU exhibition in January 2025, the company presented its first fully circular aluminium window (see “Best practice”): “AW Circular” was developed to reduced resource use, emissions and waste during the product life cycle, while helping to close resource loops. Furthermore, different carbon reduction measures were implemented for AW Circular. These include the design that makes efficient use of materials, an increased proportion of recycled material and the use of recycled components.

In the PVC business, in which Schüco produces the material itself, it was possible to further increase the proportion of recycled material in the products from an average of 21% (2023) to 24% (2024). At the same time, new material versions with designated proportions of recycled material were introduced on 1 January 2024 (see “Best practice”).