Assembly

Innovative machinery for optimising assembly processes

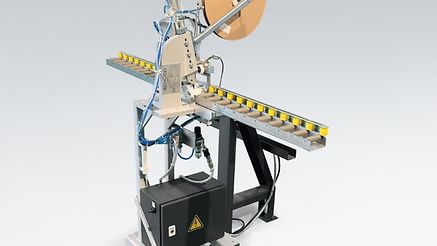

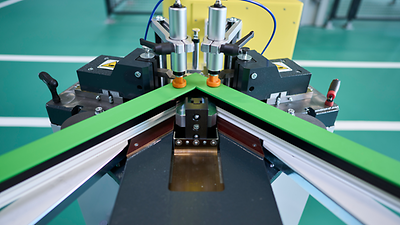

Assembling cut profiles is an essential process step in metal fabrication. The aim of Schüco Fabrication is to optimise assembly processes in the fabrication set-up of our metal fabrication partners, whether it's with the latest corner crimping machines, locking bar machines or gasket cutting machines.

Optimum unit fabrication thanks to our assembly machines

With the Schüco machinery portfolio for assembly, manual processes by eye are a thing of the past. We automate your fabrication processes and guarantee overall process reliability in fabrication.

Assembly – the basics

Why is optimisation of window assembly so essential?

Why is optimisation of window assembly so essential?

Window installation or the assembly of doors and façade units can take up more or less time, depending on the level of automation in your fabrication set-up. Innovative solutions which support you effectively during fabrication make the key difference, along with the practical skills of your employees. Schüco Fabrication can provide these kinds of solutions.

In over 70 years of producing windows, doors and entire building façades, we asked ourselves at a fairly early stage: how can this production be improved? How can we make it more efficient and faster?

Schüco Fabrication was created as an answer to this and other questions – with numerous ideas for the automation of the entire production chain for windows, doors and other units: for pre-fabrication, machining, drilling and punching or for window assembly.

When should I automate my fabrication process?

When should I automate my fabrication process?

The competition has really ramped up in recent years in the area of window and door construction. In addition to quality, individual, tailored offers and, above all, fast production and delivery times, have become key factors in ensuring a window fabricator's success.

Here you can find the right machinery for the job. Machinery which you can use to fabricate faster and in greater quantities, all while ensuring top quality. Machines like these: