Digital solutions from Schüco

For everyone and everything

The goal of digitalisation is clear: it’s about improving the entire value chain and making it more efficient. With its digital solutions, Schüco is taking a firm stand alongside its customers. We support all of our users to make the digitalisation process what it should be: simple, efficient and beneficial.

Schüco is your partner for digitalization

Seize digital opportunities with Schüco

The goal of digitalisation is clear: it’s about improving the entire value chain and making it more efficient. In the construction industry, this affects every process, from design and quotation, to planning and fabrication, all the way through to installation on site and the operation of a building.

With its digital solutions, Schüco is taking a firm stand alongside its customers. This means that we not only have solutions for individual challenges, but are making systematic improvements for architects, specifiers, fabricators and building operators. Our customers know that we understand and accept requirements and turn them into future-ready solutions.

Schüco is your partner for the future. No one accompanies its partners on the road to the digital future as closely and comprehensively as us. We focus on platforms and apps, intelligent machines, and the use of sensors and data for sustainable and efficient processes in the construction industry.

Digitalisation is complicated and multi-facetted and can't just be done overnight. Schüco is well aware of this. We support all of our users to make the digitalisation process what it should be: simple, efficient and beneficial.

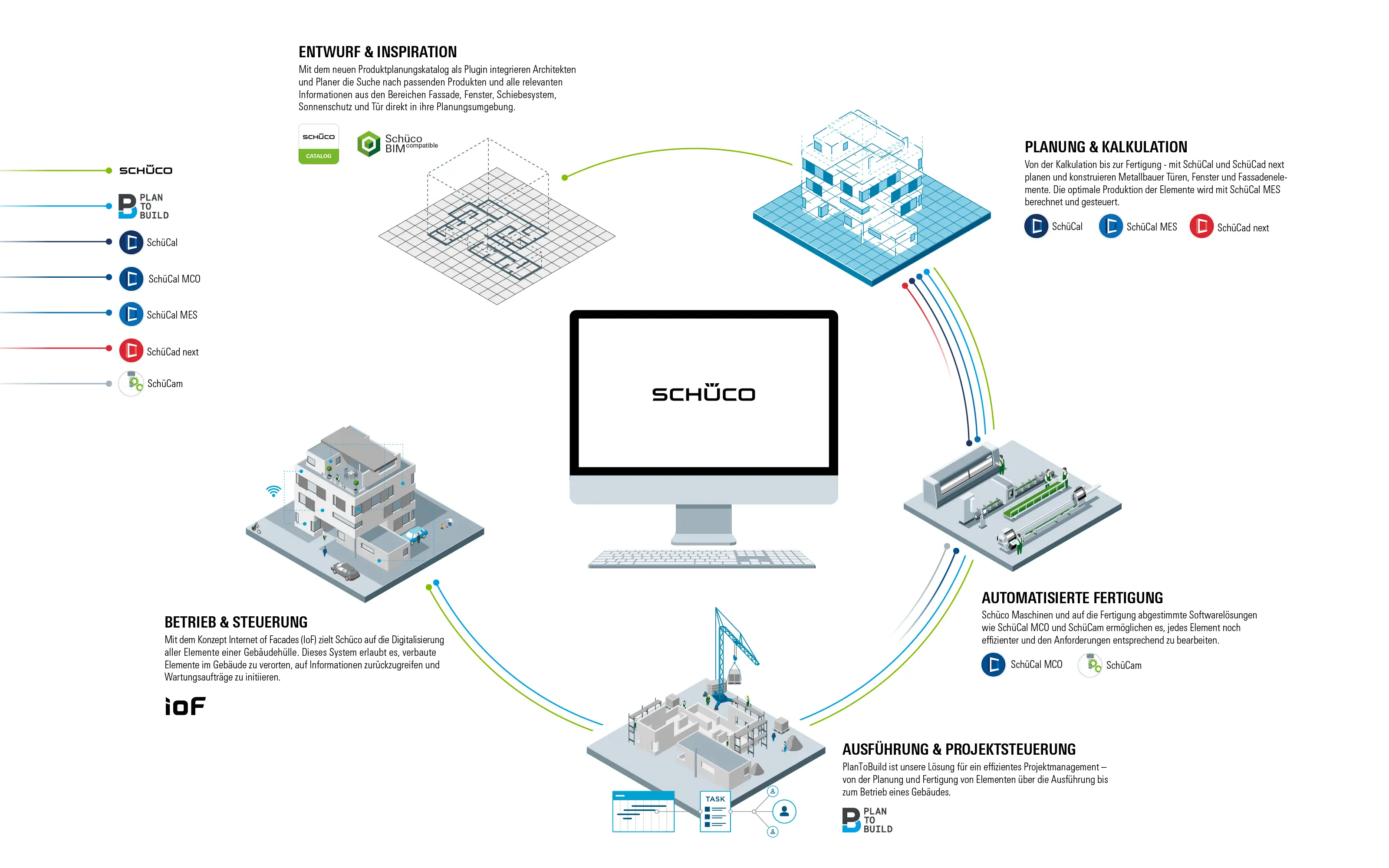

The largest portfolio of digital solutions in the industry by far – from planning through to operation

Schüco looks at digitalisation holistically. But what exactly does that mean?

Building projects are composed of many process steps that are closely linked with one another. So it is important to Schüco not to look at the individual processes in isolation. With digital solutions at every stage of the process – from the initial idea to fabrication and use in the building – we remain consistent. Handover points and interfaces between the systems ensure that digital services and products are integrated seamlessly together. For Schüco, this means being digital in every aspect.

What does that actually look like?

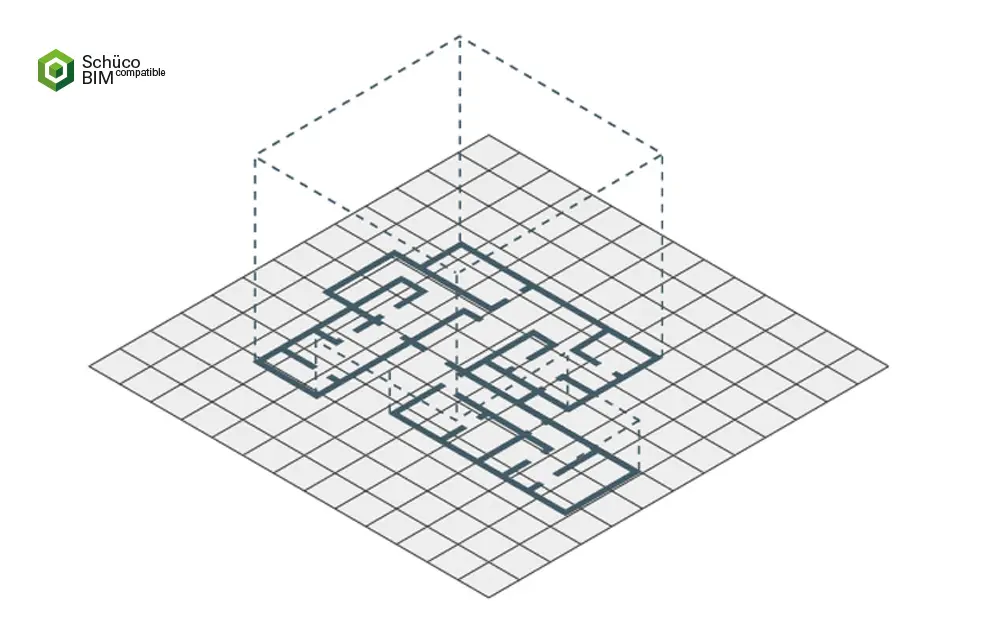

Digital modelling with Schüco

With the digital product catalogue from Schüco, architects and specifiers can quickly and easily find the right product solutions and all the relevant information for façades, windows, sliding systems, sun shading and doors centrally on one platform. Designed as an intelligent means of assistance by and for architects, the product catalogue allows you to quickly search for and compare products perfectly tailored to your building project with just one click – an important step in increasing productivity during the concept and development phase. The digital product catalogue can be integrated directly into your planning software as a plug-in. This allows data such as product information and highly detailed BIM objects to be seamlessly transferred while eliminating sources of errors. With the aid of Schüco BIM, the selected configuration with all its items is transferred to the metal fabricator for further processing via a web interface.

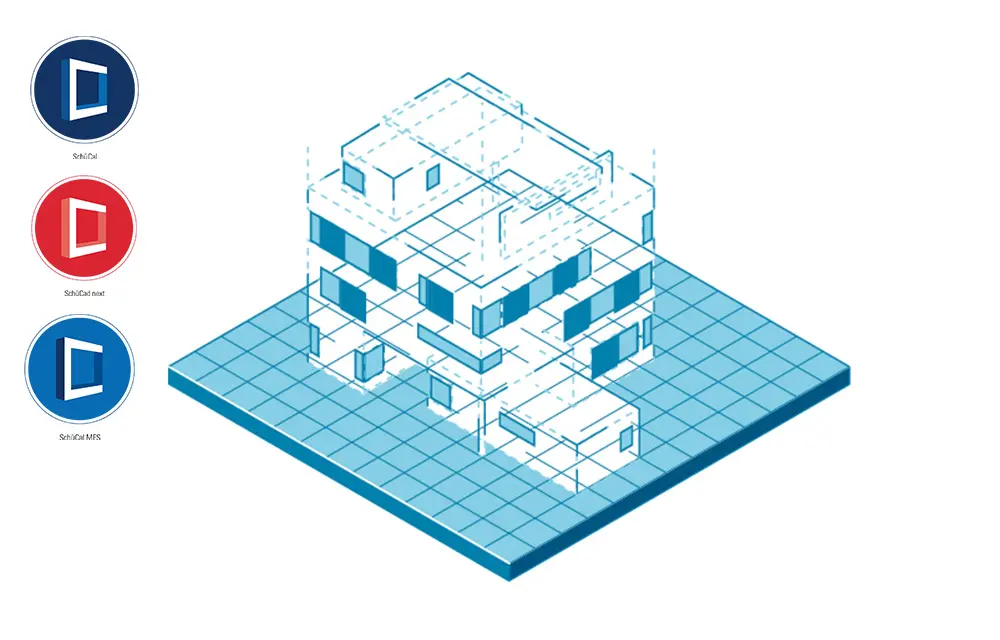

Planning and calculation

Once the technical specification for the façade unit has been made, there is the detailed plan. SchüCal is our answer to the demand for a calculation and fabrication tool. With its 3D core, it is the leading calculation and order processing software in the industry. You can use SchüCal to simplify quotation and order processing, and speed up the work, from calculation through to fabrication. The fabrication time calculation function ensures cost certainty and convenience. With SchüCad Next, the next generation CAD software for metal fabricators, you're sure to see results quickly. Optimised interfaces guarantee a flexible exchange of data and up-to-date article information ensures your construction process is always reliable.

SchüCal MES

The planned and calculated unit is now ready for fabrication. With the addition of SchüCal MES (Manufacturing Execution System) to the SchüCal product family, you have an add-on which allows you to control and monitor production processes. All the relevant information on carrying out the individual fabrication steps is always available at the right time and the right workstation.

This level of fabrication control creates transparency. That in turn saves time and significantly improves production quality. MES is the essential step towards a digital, paperless fabrication environment, without the need to search for the necessary information. The ideal addition to the Fabrication Data Center, MES enables a guided production process while simultaneously documenting product knowledge digitally. This makes it popular with everyone from the company management to the team in the workshop. It is easy to use, which means that even new employees can quickly get to work with the MES.

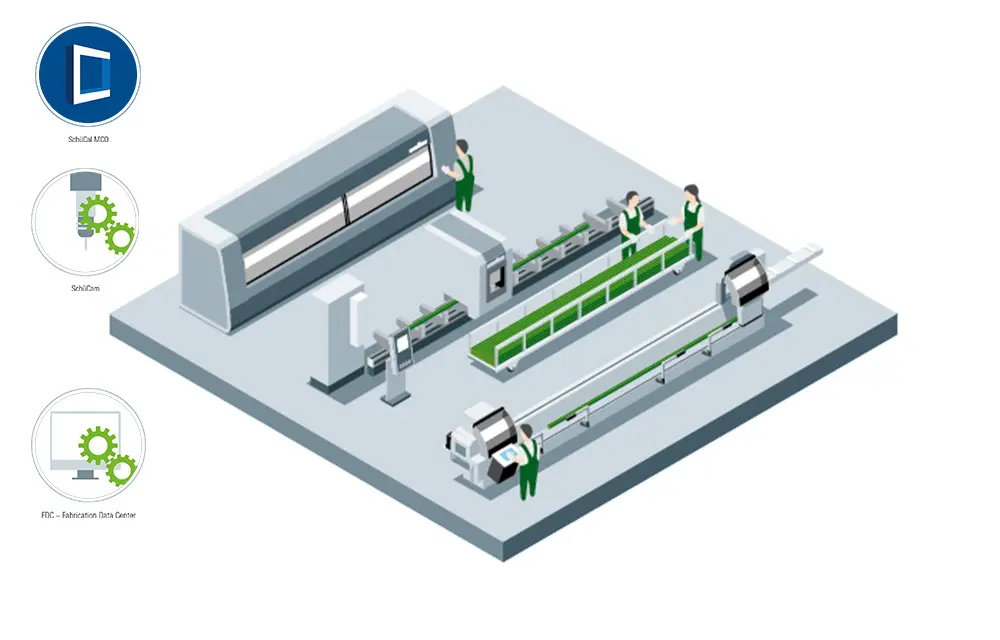

Automated fabrication

MCO from SchüCal – three letters for perfectly managing Schüco machinery. The new Machine Control Operation (MCO) mode of SchüCal allows our customers to immediately start adapting the way they machine profiles with an improved processing mode. The graphic user interface facilitates intuitive operation so that processing time is reduced and errors are avoided.

With SchüCam and its integrated optimisation algorithms, the most effective processing sequence to fabricate the respective unit is automatically calculated, visualised and communicated to the Schüco machinery.

Schüco machinery and software allows each unit to be processed more efficiently and more in line with requirements. However, perfectly coordinated processes not only require machinery and software, they also need customer-specific workshop concepts. Only if machinery, software and working steps are all in harmony can fabrication reach its full potential.

Project management

PlanToBuild is our solution for efficient project management – from planning and fabrication of units to demolition on the building site. Transfer your calculated unit with all the important information directly from SchüCal into your digital planning system. The all-in-one project management software for window, door and façade construction is designed for quick and reliable management of building projects – for both small and large companies.

Operation

Over 90% of all currently installed units are not fitted with built-in intelligence. That means that a lot of data in and around the building envelope is unknown and cannot be used. The question is how can such a large number of units be brought up-to-date with the modern world, or rather: how can they be converted into smart units?

With the Internet of Façades (IoF) concept, Schüco is aiming to digitalise all the units in a building envelope. This system allows facility management to locate installed units, including existing ones, in the building model, to access information and to trigger maintenance orders. An automatically generated project report in PlanToBuild provides operators with a complete overview at all times.

Now things have come full circle. With its digital solutions, Schüco provides support for every process. We have fostered innovation by bringing our planning and construction products to the market to create added value for everyone involved in the building industry and to maximise the full potential available through standardisation, automation and digitalisation.

Additional digital tools & services

Building Skin Control

Digital solutions for clients

Many benefits as a registered user:

- Work material (e.g. tender specifications, CAD data, catalogues)

- Software & Tools

- Note content

- Direct contact to Schüco