New generation of products from Schüco

with future-orientated ecological materials

The green generation of aluminium products

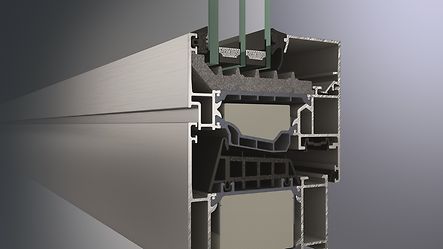

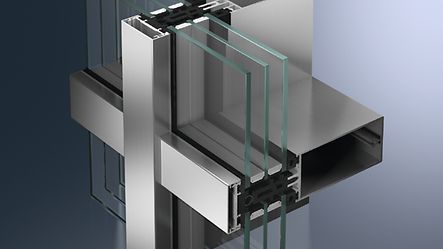

The FW 50+.SI Green façade system and the AWS 90.SI+ Green aluminium window system integrate components such as insulating bars, gaskets and pressure plates with a proportion of renewable materials. This means that fossil fuels are substituted in part, reducing the energy requirement for the production of raw materials. This development is possible due to the plant species Ricinus communis. Sebacic acid is derived from the seeds of this plant, which is used to manufacture polyamide. Polyamide created in this way forms the basis for the pressure plates of the FW 50+.SI Green façade system and for the "green" insulating bars which are integrated into the Schüco AWS 90.SI+ Green window system.

The oil from the seeds is even used for the foam of these insulating bars without the need for chemical processing. Schüco is also making a marketing contribution for the transfer of biotechnology for gaskets in both of these profile systems, by using EPDM (synthetic rubber) made from sugar cane or bio-ethanol.Equipped with plastics containing a significant proportion of renewable raw materials, these windows and façades now make a double contribution to the reduction of greenhouse gases, since they have a lower potential for global warming

This means that using renewable raw materials releases fewer greenhouse gases into the atmosphere during manufacturing and it also conserves natural resources. By integrating renewable raw materials into aluminium windows and façades with thermal insulation to passive house standard, Schüco is demonstrating its approach towards energy-efficient and sustainable construction.

Combination of sustainability and energy efficiency

In Germany, thermal insulation is the decisive factor in the energy revolution. Many local authorities have already pledged to implement thermal insulation to passive house level as standard when constructing new public buildings. The Schüco AWS 90.SI+ Green window system and the FW 50+.SI Green façade system fulfil precisely these requirements. Both constructions combine the advantages of durable aluminium with thermal insulation to passive house standard, thereby conserving natural resources and reducing CO2 emissions. Equipped with plastics containing a significant proportion of renewable raw materials, these windows and façades now make a double contribution to the reduction of greenhouse gases, since they have a lower potential for global warming. This means that using renewable raw materials releases fewer greenhouse gases into the atmosphere during manufacturing and it also conserves natural resources. By integrating renewable raw materials into aluminium windows and façades with thermal insulation to passive house standard, Schüco is demonstrating its commitment to energy-efficient and sustainable construction.

PVC-U - making a contribution towards sustainability with environmentally friendly systems

Schüco PVC-U systems are 100% recyclable. They can therefore be easily incorporated into the recycling system. Furthermore, Schüco has not used lead stabilisers in its PVC-U since 2010. Heavy metal-free products based on calcium-zinc compounds are used instead. Schüco PVC-U systems are therefore lead-free. Consequently, Schüco has already achieved the aim of “Vinyl 2010”, the voluntary commitment of the PVC industry to substitute materials containing lead by 2015.

Schüco Alu Inside

Schüco uses a patented aluminium composition construction in the Schüco Alu Inside profile system. This prevents thermal bridging, making the Schüco Alu Inside profile system a passive house-certified window system with optimum thermal insulation properties.

Schüco Corona SI 82

The Schüco Corona SI 82 window system, which is suitable for passive housing, offers excellent thermal insulation properties thanks to its 6-chamber technology and the increased basic depth of 82 mm. This system therefore allows low-energy window and door units to be constructed without expensive additional equipment.

Steel systems meet the highest requirements in terms of climate protection, value retention and durability

HI systems made from durable materials

The VISS HI façade system and the new Janisol HI window and door system are setting new standards in climate protection and construction using sustainable materials. Steel is the material for buildings with a sustainable design, both in the primary load-bearing structure and for the complete building envelope. Steel, glass and concrete are perfect together due to their almost identical expansions in length. This allows the materials to work in harmony with one another, which is unique in the construction industry.

The VISS HI steel façade system boasts optimum thermal transmittance values to passive house standard. Together with the new Janisol HI steel system for the window and door opening units, the most sustainable building envelope is a success due to the most durable material which retains its value to an extremely high degree. Detachable connections also ensure that it is easy to dismantle at the end of its life cycle. New steel façades can be produced from the dismantled material – the material is 99% recyclable.