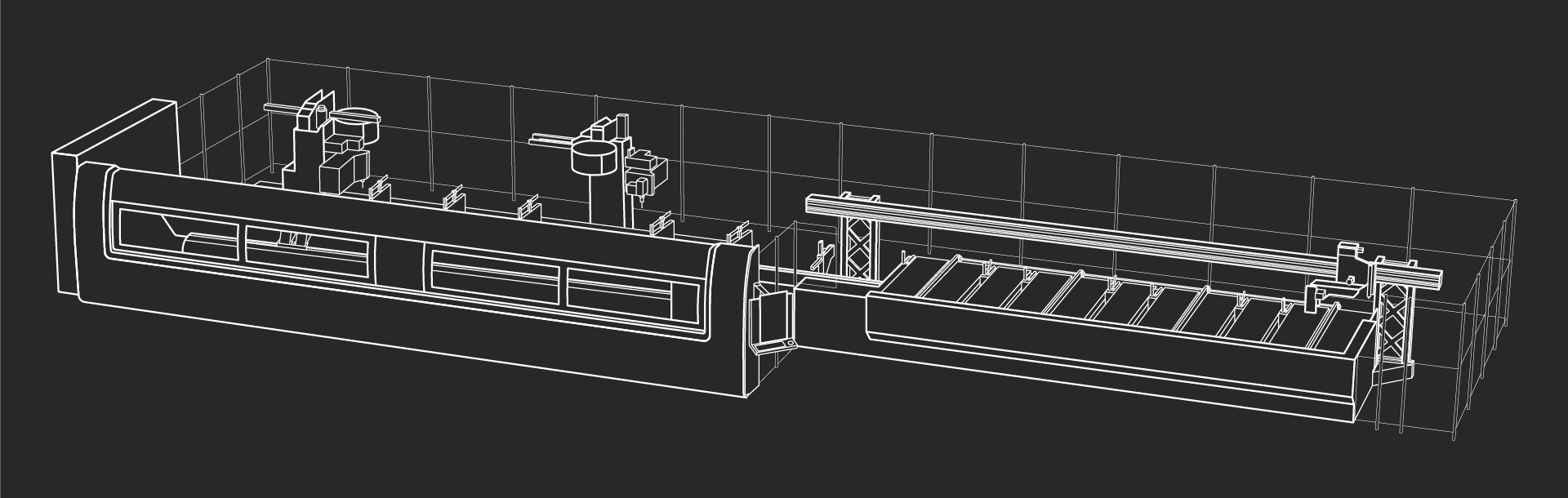

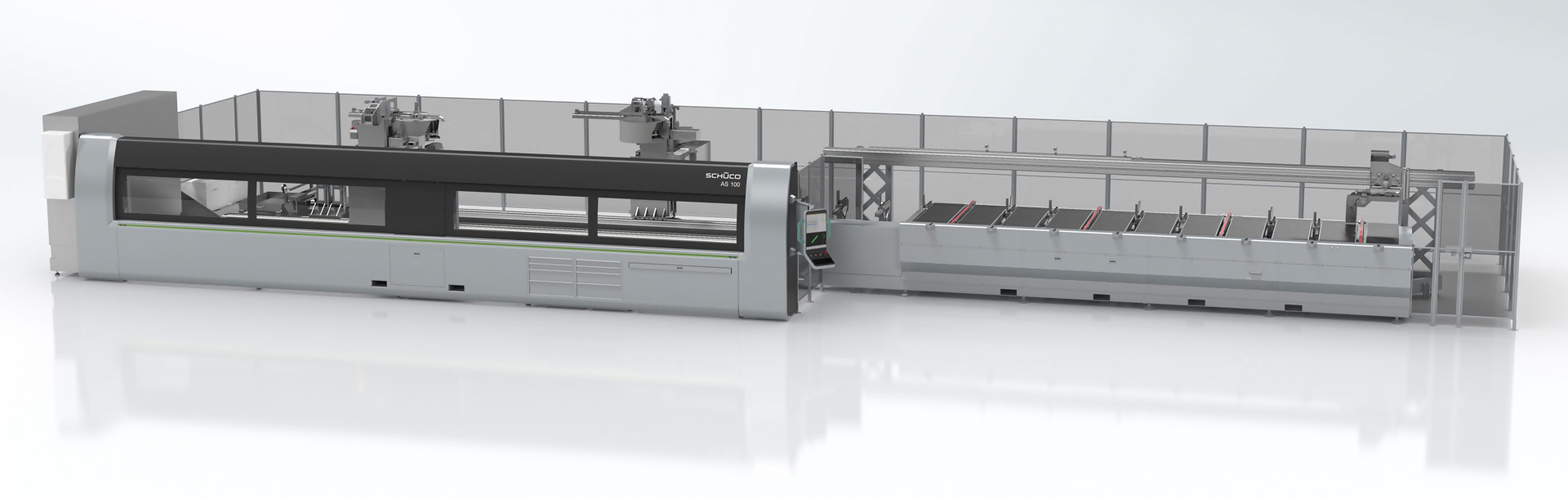

The new Schüco AS 100 fabrication system

With its myriad cutting and notching options, the new Schüco AS 100 fabrication system is as flexible as a state-of-the-art 5-axis machine. With its speed, continuous fabrication process and operation that is sometimes unmanned, the machine offers all the benefits of a continuous feed system. The new titan of fabrication optimisation further impresses with its low space requirements. This is due to a combined loading and unloading magazine, which can hold profiles up to 7500 mm. At the heart of the system is the processing station. A 9 m machine bed accommodates not only the two 5-axis towers, which process the profiles on six sides, but also five self-positioning clamps. The unprecedented combination of reliable clamping, surface protection and felxibility facilitates easy handling of different profile geometries.