CNC machining

Schüco Machine AS 100

Schüco Machine AS 100

The new fabrication system with numerous profile cutting and notching options is as flexible as a modern 5-axis CNC machine. With its high speed and continuous fabrication process, the Schüco AS 100 also offers the benefits of a continuous feed system. In addition to its pioneering high performance in terms of fabrication optimisation, the system impresses with its minimal space requirements. This is ensured by a combined loading and unloading magazine, which can hold profiles up to 7,500 mm and thereby enables the longest unmanned operation of the machines available on the market. The heart of the machine is the processing station: a 9 m machine bed accommodates not only the two 5-axis towers, which process the profiles on four sides – including cutting and end-of-profile processing, but also five self-positioning clamps.

Schüco Machine AF 500

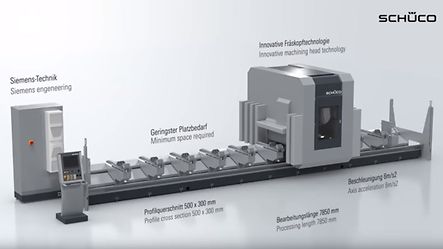

Schüco Machine AF 500

Portal CNC machine with cutting option, including PC control, operated directly from SchüCal.

The Schüco Machine AF 500, featuring 6-side machining, is an efficient processing machine for aluminium and steel profiles.

- Bar processing with cutting possible

- The locating edge of the profiles is shifted forwards, making it easier to insert them

- Machining head mounted on one side (can be rotated using two numerically controlled movement axes)

- Steel profile processing (S235 to approx. 5 mm wall thickness)

- 3 processing modes: Individual bars, multiple bars (up to 4 profiles) and alternating operation

- 8 individually operated and adjustable clamps

- Tool changer is carried along with the portal

- High resolution, absolute position-measuring system

- Infinitely adjustable pivoting action of the B and C axis via the servo axis

- Portal beidseitig mit Sicherheitsschaltleisten in Bumper-Ausführung

- Easy-to-use control panel with 19” touch TFT colour display

Technical Data:

Number of controlled NC axes: | 8 |

Processing length: | 7850 / 7300 mm |

Max. processing speed X / Y / Z: | 80 / 60 / 40 m/min |

Rotation of B axis: | ± 180° (swivels about an angle of 55°) / 20° underpivoting |

Rotation of C axis: | ± 360° (rotates about the Z axis) |

Tool holder: | HSK-63F |

Speed range: | 0 – 24000 rpm |

Milling motor output: | 15 kW |

Number of spaces in moving tool magazine: | 20 |

Positioning of the clamps: | automatic |

Number of clamps: | 8 |

Maximum number of clamps: | 10 |

Max. cross section (W x H) / length – single bar processing: | 450 x 350 / 7300 mm (for 250 mm tool length); 500 x 350 / 7300 mm (for 200 mm tool length); 7850 mm without end-of-profile machining |

Min. cross section (W x H) / length – single bar processing: | 30 x 30 / 300 mm (for 200 mm tool length) |

Schüco Machine AF 500

Schüco Machine AF 450

Schüco Machine AF 450

CNC machine, including PC control, operated directly from SchüCal

- 3-side machining of aluminium and steel profiles

- 3 operating modes:

- Single-bar with extra length

- Multi-bar with different contours

- Alternating operation with ASP system - Individually operated and adjustable clamps with vertical clamping fix

- 7500 mm machining length

Technical Data:

Number of NC driven axes: | 4 + tool changer |

Max.processing speed X/Y/Z: | 80 / 60 / 40 m/min |

Rotation of A-axis: | Continuously from +90° to -90° |

Tool mount: | SK 30 |

Speed: | to 24000 rpm |

Milling motor output: | 7,5 kW at 6000 - 12000 rpm (S1) |

Number of spaces in moving tool magazine: | 12 |

Positioning of the tension blocks: | automatic |

Number of tension blocks: | 8 |

Weight: | 5800 kg |

Max. Cross selection (W x H) / Length Single bar processing: | 420 x 300 / 7500 mm (at 110 mm tool-length) |

Schüco Machine AF 310

Schüco Machine AF 310

CNC machine operated directly from SchüCal

- Machining on 3 sides

- 4000 mm machining length

Technical Data:

Number of NC driven axes: | 4 |

Range of travel of the axes X/Y/Z: | 4000 mm |

Max.processing speed X/Y/Z: | 150 / 40 / 40 m/min |

Rotation of A-axis: | continuously from +110° to -110° |

Tool mount: | HSK-63F |

Speed: | up to 24000 rpm |

Milling motor output (fromn speed): | 8.5 KW at 6000 rpm (S1) |

Number of spaces in moving tool magazine: | 10 |

Positioning of the tension blocks: | automatic |

Number of tension blocks: | 5 |

Weight: | 3600 kg |

Cross selection (W x H) / Length: | 300 x 190 / 4000 mm (at 130 mm tool-length) |

Cross selection (W x H) / Length, with pivoted A-axis: | 300 x 170 / 4000 mm (at 150 mm tool-length) |

Schüco Maschine AF 310

Schüco Machine AF 250

Schüco Machine AF 250

Compact 3-axis CNC machine with a pneumatic rotating support table – specially designed for the fabrication of windows and doors from aluminium and steel profiles

With machining lengths of 3200 mm or excess lengths in two stages, 3-sided processing and machining of the end of the profile, the Schüco Machine AF 250 offers efficient application options for the economical, high-quality fabrication of

Schüco window and door series.

Technical Data:

| Product Benefits: | Fabrication Benefits |

Spindle power: 3.8 kW, maximum 18,000 rpm, cooled by compressed air | Automatic tool changer with 5 spaces, optional additional tool magazine with 3 spaces |

3-sided machining of aluminium and steel profiles | 2 fixed stops: collapsible for accurate definition of the zero point, lengths of up to 6.4 m can be processed as a result |

Processing cross-section for 160 mm tool length: maximum 250 mm x 150 mm | Locating edge of the profiles is shifted forwards, making it easier to insert them |

Processing cross-section for 160 mm tool length with pivoted A-axis: maximum 200 mm x 115 mm | Safety hood for loading and unloading opens automatically |

Preparation of S235 steel up to a wall thickness of approx. 3 mm | |

Measuring stop for measuring profile length | |

Machining space fully enclosed |

Schüco Machine AF 210

Schüco Machine AF 210

The Schüco AF 210 opens up new possibilities in the fabrication of aluminium profiles for windows and doors. With this machine, manual processes are a thing of the past and profile bars measuring up to 2900 mm can be processed automatically. Furthermore, this space-saving miracle requires very little room and will fit in every workshop.

Key benefits at a glance:

- Operated directly from SchüCal or via simple in-house programming

- High degree of flexibility as automatic tool changer can be freely configured

- Versatile machining, including end-of-profile processing, with the high-quality milling motor

- High level of process reliability thanks to inherently strong machine bed

- Four manuell moving clamps allow two profiles to be machined at once

- 3-sided processing and diagonal drainage holes are easy thanks to the swivel table with mechanical clamping

- A closed machining space including an automatic cover replaces safety barriers and photoelectric barriers

Technical Data:

Number of NC driven axes: | 3 |

Range of travel of the axes X/Y/Z: | 3160 / 360 / 345 mm |

Max.processing speed X/Y/Z: | 60 / 30 / 30 m/min |

Rotation of A-axis: | 90° / 0° / - 90° pneumatic |

Tool mount: | SK 30 |

Speed: | up to 18000 rpm |

Milling motor output (fromn speed): | 3.8 KW at 12000 rpm (S1) |

Number of spaces in tool magazine: | 5 |

Positioning of the tension blocks: | manual - with examination of the positions |

Number of tension blocks: | 4 |

Weight: | 1560 kg |

Cross selection (W x H) / Length: | 250 x 116 (at 126 mm tool-length) |

Cross selection (W x H) / Length, with pivoted A-axis: | 250 x 170 (at 126 mm tool-length) |

Hint

We reserve the right to make changes to dimensions and designs in the interests of technical progress.

Illustrations may differ from the original and/or contain options which would incur an additional charge.

Many benefits as a registered user:

- Work material (e.g. tender specifications, CAD data, catalogues)

- Software & Tools

- Note content

- Direct contact to Schüco