Circular economy: Go Circular

We here at Schüco are certain of it: Buildings are the raw materials stock of the future. This is why we are actively driving forward the transition from linear to circular construction, i.e. closed recycling processes – one example of this being our Cradle-to-Cradle certified systems.

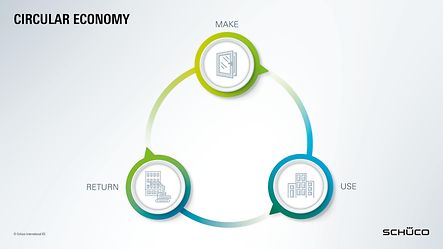

What exactly is the circular economy?

In the circular economy, materials continue their life even beyond the active usage phase without any loss in quality. Thus, in the circular economy model, what would previously have been considered construction waste is used as the base material for a new, equally high-quality product. This is the case, for example, when a façade unit is processed into a building component of equal quality after being reintroduced to the production cycle. The circular economy meets the growing demand for resources with calls to reduce waste to a minimum, reuse products and materials, and to recycle them after the active usage phase.

Our circular systems

The circular economy model we use for our aluminium systems relies on certifications in line with the Cradle to Cradle Certified® products programme. With a total of 55 certified aluminium systems, Schüco is a pioneer in the industry in applying the cradle-to-cradle principle. Find out more about our C2C-certified systems.

But it’s not just aluminium: our PVC-U products also meet high standards in terms of recyclability and reduced emissions – this was also underlined when Schüco became the first company in the industry to be recognised with the VinylPlus® product label. Find out more about VinylPlus®.

Our materials aluminium, PVC-U and steel all boast a impressive level of durability and recyclability. For example, PVC-U windows have a lifespan of around 40 years per window and can be recycled up to seven times – this therefore means that, thanks to the circular economy, the material can be used for 240 years.

Our aluminium systems are also of outstanding quality and optimal material strengths for construction, thereby ensuring mechanical robustness and excellent corrosion resistance. This ensures a long service life and makes aluminium windows, doors and façades sustainable.

What else do we do?

In order to make it attractive for the manufacturer to take back products and to ensure that materials can be reintroduced into the material cycle as easily as possible, the most important element is functioning collection and recovery systems. In light of this, Schüco has already been involved in the sector initiatives AIUIF and Rewindo for many years, in order to close off the material cycles for aluminium and PVC-U.

Industry initiatives for a functional circular economy

AIUIF

AIUIF

The objective of the AIUIF (Aluminium and the Environment in Window and Façade Construction) is to promote the disposal and processing of aluminium construction components and profiles removed from windows, doors and façades for the purpose of reusing the materials in the long term. AIUIF members, of which Schüco is one, include system vendors, manufacturers, fabricators and suppliers from all over Germany. The AIUIF carries out responsible recycling of used aluminium window profiles, almost 100% of which can be recycled.

Find out more about the work of the AIUIF.

Rewindo

Rewindo

Rewindo is a joint initiative of leading German PVC-U profile manufacturers, consisting of the previous collection systems for old windows from FREI and VEKA Umwelttechnik GmbH. Rewindo aims to increase the number of removed PVC-U windows, doors and roller shutters reintroduced into the materials cycle and to promote this practice. Rewindo is a service partner for the reuse of PVC construction products. It assists its members with all recycling issues, e.g. by providing documentation materials, needs-based collection boxes, and by issuing certificates of destruction. Rewindo’s task is therefore to inform, motivate and organise, as carelessly disposing of old plastic elements makes no sense.

Find out more about the work of Rewindo.